ERF Air Quality Emissions

Emissions from the existing facility are well within the targets as set out in the Industrial Emissions Directive (IED) (2010/75/EU). Energy Recovery Facilities operate under strict emission limits shown in IED and require a permit (issued by the Environment Agency) to operate.

The documents sets out the emissions reductions which are expected to be achieved by the proposed Energy Recovery Facility

Emissions from an Energy Recovery Facility

Environmental permits are issued by the Environmental Agency and set limits on the allowable concentration of pollutants in gaseous emissions from ERFs – known as Emission Limit Values. These limits are set out in the EU Directive 2010/75/EU on Industrial Emissions (IED). Specific Emission Limits are set for the following pollutants:

- Sulphur Dioxide (SO2);

- Nitrogen Oxide and Nitrogen Dioxide (NO and NO2);

- Hydrogen Chloride (HCl);

- Hydrogen Fluoride (HF);

- Gaseous and vaporous organic substances expressed as Total Organic Carbon (TOC);

- Carbon Monoxide (CO);

- Dust;

- Heavy Metals; and

- Dioxins and furans;

As required by the Environmental Permitting Regulations (2010) an environmental permit is necessary to in order to operate an ERF. These are enforced by the Environment Agency and often have even stricter emissions limits than the IED.

How are the emissions cleaned?

All Energy Recovery Facilities (ERF) are required to be equipped with sophisticated flue gas cleaning systems in order to minimise emissions into the atmosphere which are strictly regulated.

The Waste Incineration is not the only sector to emit these pollutants, but in general has the strictest limits placed on them. Further, high performance flue gas cleaning systems are integrated in all European incineration plants, enabling the sector to comply with lower Emission Limit Values than any other combustion industry.

Dioxins and acidic gasses (such as sulphur dioxide) will be controlled via a reactor within the facility. This is where hydrated lime is injected into the flue gas to neutralise acidic gasses, and where activated carbon is injected to remove heavy metals and dioxins / furans through a process known as adsorption. As a result of these modern technologies, emissions of dioxins from UK EfWs has decreased by 99% since 1990. The key sources now include crematoria and agricultural straw burning. Sulphur dioxide emissions previously led to an acid rain crisis in the 1970s and 1980s. Burning coal to produce power was the major contributor. However as a result of EU air quality legislation, sulphur dioxide emissions have fallen by 80% since the 1980s and the issue of acid rain has been successfully addressed. The new ERF, like the existing plant, will neutralise hydrogen chloride and sulphur dioxide in the reactor through the use of lime.

NLWA is proposing to install a flue gas cleaning technology that offers the highest degree of air emission abatement. Therefore, NLWA is delivering the wet and combined flue gas treatment options together with selective catalytic reduction (SCR) for nitrogen oxide (NOx) abatement.

Wet and combined flue gas treatment plants can achieve the same emission limit values. Both systems produce emission limits far below the levels required by the European Union (EU) Industrial Emissions Directive (IED). The SCR system can achieve a NOx emission limit well below half the current Industrial Emissions Directive emission limit of 200mg/Nm3, down to as low as to 25 mg/Nm3.

What pollutant reductions can be achieved?

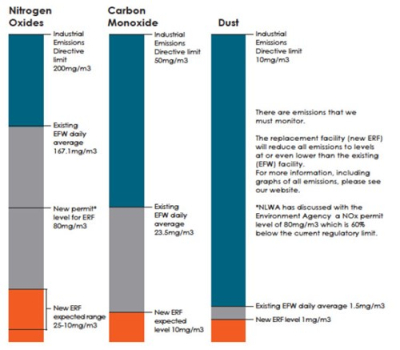

For each pollutant, the figure below shows the levels of operational emissions reductions achieved by the existing EfW facility. In most cases the existing facility reduces emissions to well below the IED daily limits (also shown).

The expected emissions reductions which may be achieved by the proposed ERF are also provided in the same figure. The expected emission ranges are provided to show how some pollutants may vary depending on, for example, the composition of the incoming waste stream.

For the majority of pollutants the proposed ERF is expected to reduce emissions to levels that are equal to or better than the existing EfW facility. NLWA has discussed with the Environment Agency a NOx permit level of 80mg/m3 which is 60% below the current regulatory limit. As discussed, the proposed SCR system is capable of reducing NOX emissions levels below to 25 mg/Nm3.

For some pollutants the levels of emissions are extremely small and are reduced to the point where they are barely detectable (represented by a 100% emissions reduction).

Want to know more?